PEBCO® – Building A Better Line of Equipment

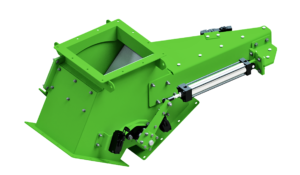

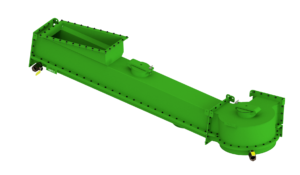

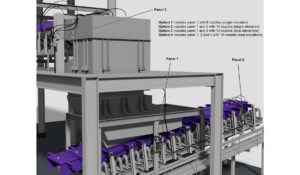

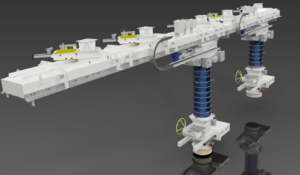

PEBCO®’s line of standard products come ready to install into your system. Our selection of high-quality, expertly engineered products include slide gates, diverters, loading spouts and chutes, dust suppression systems, and more. In addition, they all come with the ability to be fully customized to meet your needs. Our engineers understand every application can be unique and the proper materials will literally make, or break, your system.

We’re pioneers and inventors. We think outside the box. We’re passionate about what we do, and we care.

The types of materials your company is handling, plus the environment in which they are processed, will make some parts and materials function better than others. Trust us, we know. We’ve been building better products for over 40 years. Our R&D Team continues to find even better solutions, and that sometimes means inventing a new component or machine!

By installing the best quality products, we ensure you’ll get the best possible performance out of your system. Down time is not productive time.

PEBCO®’s standard products are constructed of carbon steels with 400 BHN liners. However, a variety of stainless steels, aluminums, and exotic materials such as Inconel®, Monel®, and even polymers are available for basic construction. Like all other material selections, liners are chosen based on the application. Liner materials range from AR plates and weld overlays to ceramics, Tivar®, and Teflon®.

Actuation options include manual, electric, pneumatic, and hydraulic to fit the requirements of your application. We use only the best components from the most reputable manufacturers such as Parker, IMI Precision Industries (Norgren Pneumatics), FloServe (Limitorque Actuators), (ANDCO Actuators), Rotork Controls, Continental Hydraulics, and many more.

When required, a wide array of sealing options are available to fit your application. Our typical offerings include a variety of elastomers such as neoprene, silicone, EPDM, Viton, urethane, and more. Rigid sealing systems are available in Tivar® UHMW, Teflon®, nylon, and spring steel. Closed cell foam, felt, and PEBCO®’s custom designed, live-loaded seals are used when extreme compliance is required for sealing or for gasket applications.

All electrical components provided on PEBCO® equipment carry a minimum rating of NEMA 4. However we can custom specify each and every device used on your equipment to fit the individual requirements of your application. From common NEMA and UL ratings to international hazardous duty classifications, PEBCO®’s equipment will arrive with the proper ratings and markings for your industry and local requirements.

PEBCO® Product Families:

Many of our products also come with options for dust suppression, collection, and capture, drastically improving dust emissions. As industries are forced to adhere to stricter guidelines, we aim to always be one step ahead to keep your business in compliance.