Uni-Load® and Batching Systems

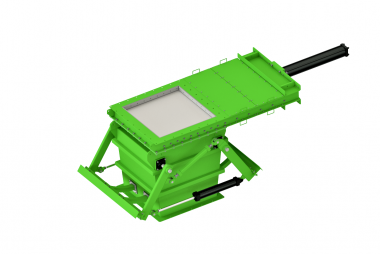

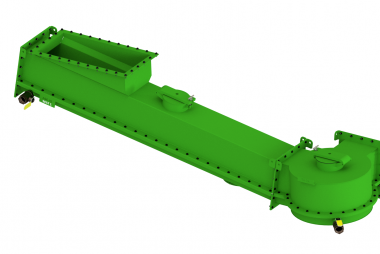

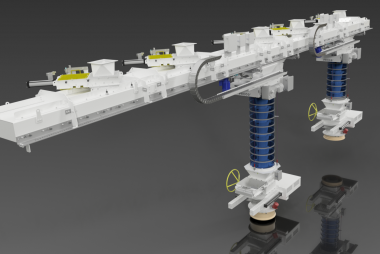

The PEBCO® Uni-Load® System is used for in-motion volumetric loading of open-top trucks and railcars. Loading rates as high as 6,000 TPH can be achieved with the PEBCO® Uni-Load® Chute. Materials such as coal, iron ore, and petroleum coke are typically discharged into moving railcars using automation controls to start and stop the loading process to achieve an accurate loaded weight and distribution. Manual control of the system can also be used when these factors are not as critical or when loading trucks for shorter distance hauls.

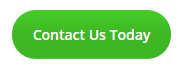

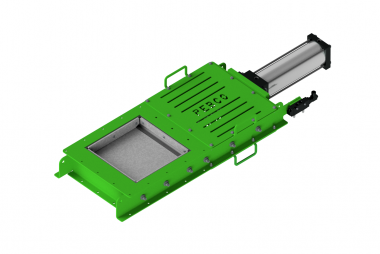

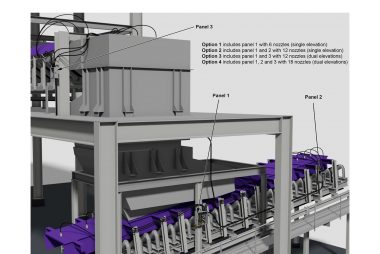

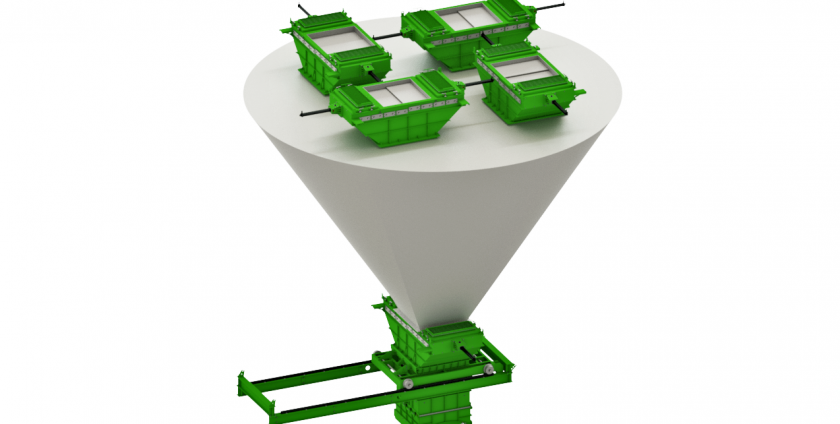

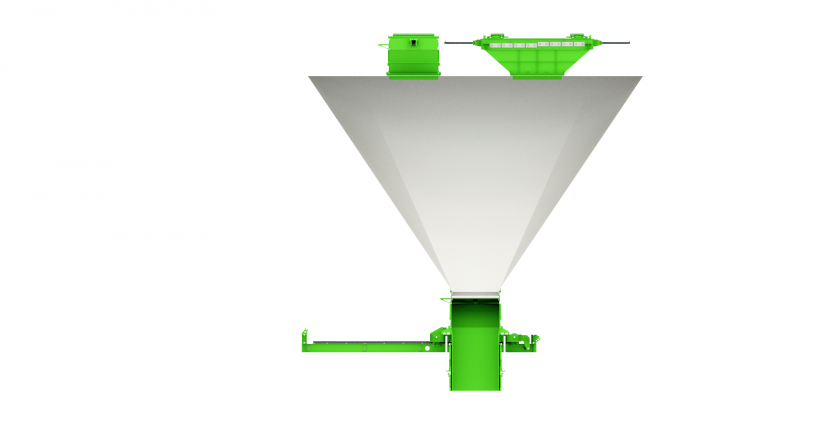

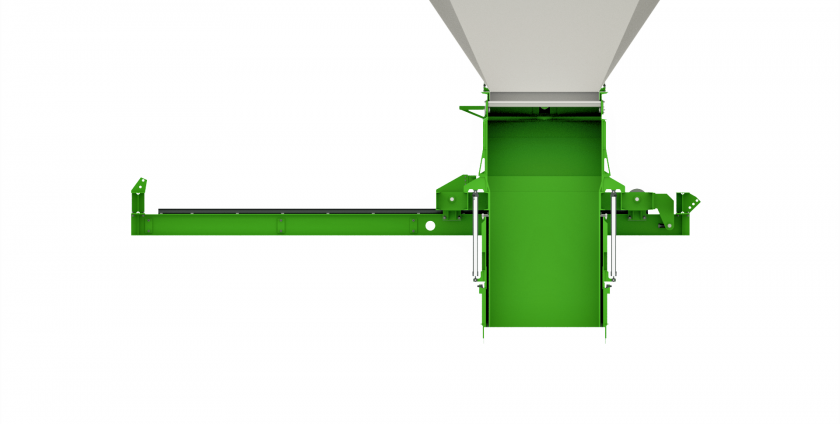

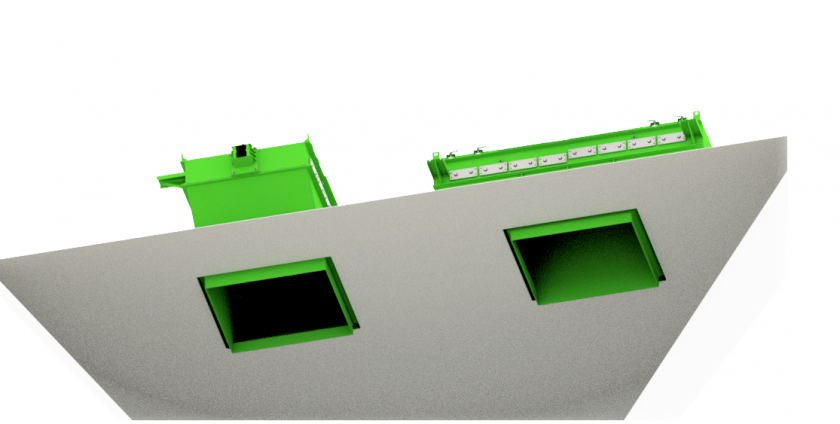

The PEBCO® Batch Loading System pre-weighs material before loading it into the truck or moving railcar. This process provides loading accuracies of +/- 0.1% helping to reduce back-charges and fines from the carrier. Charge gates control the flow of material from the silo or surge bin into the Weigh Bin, which is monitored by load cells. A discharge slide gate and rectangular telescoping chute control the discharge of material into the railcar. Optical sensors allow the control system to adjust open and close positions to insure proper distribution of the product front to rear. This minimizes differential weights between axles as both differential and gross weight error can result in fines from transportation companies.

PEBCO® proudly designs both the hydraulic and controls systems that drive each of these unique loading solutions. To learn more about which PEBCO® Loading System is right for your application, contact us today and one of our expertly trained sales staff will get you the answers you need.

For a list of PEBCO®‘s material, actuation, sealing, and electrical options, visit our Product Families page.